| Freshening a

rifle barrel is a method for completely renewing the

rifle bore without reaming it smooth and re-rifling it.

The tools needed are easily made in the shop and,

although labor intensive, the work process is easily

mastered. Many period accounts refer to freshening a

barrel and, although nearly impossible to date, slugs

like the two described here survive.

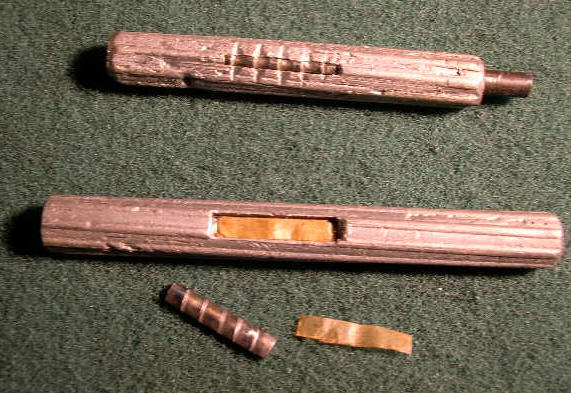

Start by casting a lead slug around either a wood or

metal rod. I have used both pure lead and wheel weight

metal and don't see much difference. For a .50 Cal. the

rod can be 1/4 or 5/16 and I notch it so the slug will

grip. (That may not be necessary when cutting a new

barrel but when I used to fresh originals I'd often end

up pounding the slug through the barrel.) Just put a

cloth patch on the rod and center it in the muzzle.

Finished slug should be 5-6 inches long.

I cut the groves first then make a new slug for the

lands but if you are removing only 5 thousands or so you

could easily just inlet the lands saw in another part of

the same slug. Old barrels were sometimes so rough we

took out 3 or 4 calibers and then you definitely need a

new slug for the lands.

The teeth of both cutters are sharpened more like

scrapers than file or saw teeth. In other words the

front face is more or less 90 degrees. The teeth are

deliberately spaced unevenly to prevent chatter. I stone

the actual cutting edge real smooth. You don't want a

chip fusing to the edge and gouging the barrel.

I use the real thin paper that comes in new shirts as

shim material. It has more body than cigarette paper

which some recommend. Start by getting the slug moving

smoothly with no cutter. Inlet the cutter so it is just

below grade. The inletting deforms the slug so you will

need to get it working through the barrel again. Scrape

or file the high spots.

Always cut from breech to muzzle. You won't be able to

see the groves at the breech so make a mark on the

barrel face for lining up with a grove. You may be able

to see little numbers on the front end of the slug in

one picture. I cut grove 1, 2, 3 etc. go around until it

almost stops pulling chips and then shim. Start the new

shim in a different grove because it will cut the most

on the first pass--before it compresses. Using that

thickness of shim I usually go all the way around 3 or 4

times before shimming again. Both cutter in the pictures

have a notch at the front so they can be prized out of

the slug.

I place a dish or box with a cloth pad at the muzzle end

so when the slug drops out of the barrel in has a very

short fall. Don't want to jar the cutter out and lose

any shims. Clean chips and oil heavily. Job will take

better part of a day to re-cut a new barrel and two or

three days for a rusted out old one.

Forgot to mention two things about the lands saw. It can

be wider than the lands because the outside edges are

not touching anything. The lands saw is a slightly

quicker radius then the bore so it starts cutting only

in the center of the lands. When you finish the bore

will be like some 19th century rifles and all the tool

marks will be parallel to the rifling so there is less

patch cutting. The hollowed

lands were specified for contract rifles about 1808-1810

but I suspect they go back much farther.

(top) |